Hey there! Ready to dive into the exciting world of AI-driven quality control? Well, buckle up because we’re about to embark on a journey that will revolutionize productivity and efficiency in the manufacturing industry. In this article, we’ll explore how artificial intelligence is transforming the way we ensure the quality of products, improving processes, and saving valuable time and resources.

Picture this: a bustling factory floor, filled with automated machines and buzzing with activity. Amidst the hustle and bustle, AI-driven quality control systems are silently working their magic, meticulously inspecting every product with unparalleled precision. No more human error or subjective judgments. With advanced algorithms and machine learning capabilities, AI is taking quality control to new heights, ensuring that every item that leaves the production line is flawless.

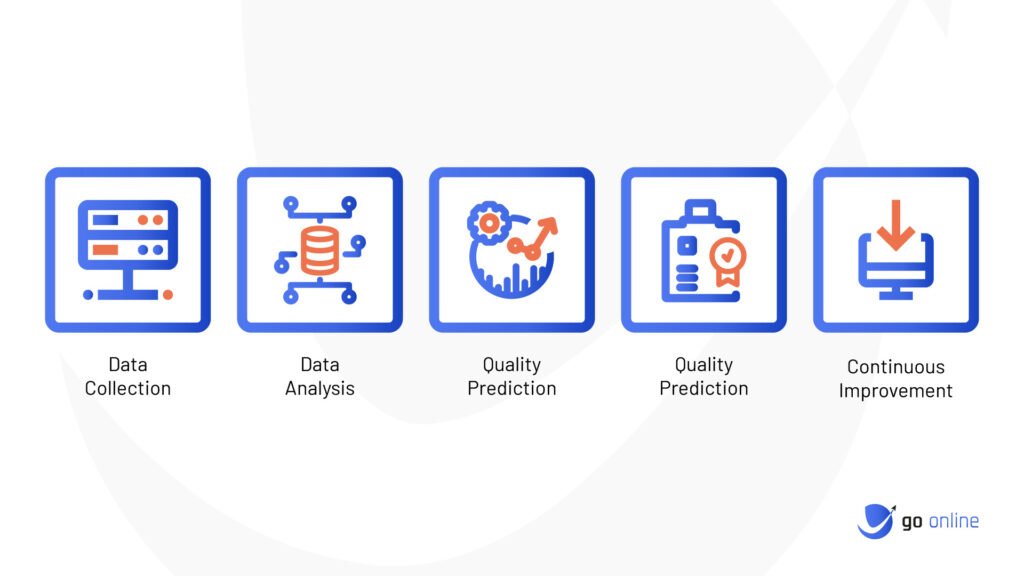

But what exactly does AI-driven quality control entail? Well, it’s all about leveraging the power of artificial intelligence to analyze vast amounts of data, identify patterns, and make informed decisions. By harnessing the capabilities of machine vision, deep learning, and predictive analytics, manufacturers can streamline their operations, detect defects in real-time, and optimize the production process. The result? Enhanced productivity, improved efficiency, and a significant reduction in waste.

So, get ready to discover the incredible potential of AI-driven quality control. From identifying defects with unmatched accuracy to automating repetitive tasks, this technology is revolutionizing the way we ensure product excellence. Let’s dive in and explore the limitless possibilities that await us in this exciting new era of manufacturing.

AI-driven Quality Control for Enhanced Productivity and Efficiency

In today’s fast-paced and highly competitive business landscape, companies are constantly searching for ways to improve productivity and efficiency. One area that holds great potential is quality control. Traditionally, quality control has been a labor-intensive and time-consuming process, but with the emergence of artificial intelligence (AI), businesses can now take advantage of advanced technologies to streamline their quality control operations.

AI-driven quality control refers to the use of AI algorithms and machine learning techniques to automate and enhance the accuracy of quality control processes. By leveraging AI, companies can not only reduce human error but also gain valuable insights into their production processes, leading to increased productivity and efficiency. In this article, we will explore the benefits of AI-driven quality control and how it can revolutionize the way businesses operate.

The Role of AI in Quality Control

AI technologies, such as computer vision and machine learning, have the potential to transform the quality control landscape. By analyzing large volumes of data and learning from patterns, AI algorithms can detect defects and anomalies in products with a high degree of accuracy. This eliminates the need for manual inspection, saving time and resources.

One of the key advantages of AI-driven quality control is its ability to detect minute defects that may not be visible to the human eye. For example, in manufacturing processes where precision is crucial, AI algorithms can identify imperfections that could impact product performance. This level of precision ensures that only products meeting the highest standards are released to the market, enhancing customer satisfaction and brand reputation.

Benefits of AI-driven Quality Control

1. Improved Accuracy: AI algorithms can analyze data with unparalleled precision, minimizing the risk of human error. This leads to more accurate quality control results and reduces the likelihood of defective products reaching the market.

2. Increased Efficiency: By automating quality control processes, AI-driven systems can significantly reduce the time and effort required for manual inspection. This allows businesses to allocate their resources more efficiently and focus on other critical tasks.

3. Real-time Monitoring: AI-driven quality control systems can continuously monitor production processes in real-time. This enables businesses to identify and address issues promptly, preventing the accumulation of defective products and minimizing production delays.

4. Cost Savings: Implementing AI-driven quality control can lead to significant cost savings in the long run. By reducing manual inspection, companies can optimize their workforce and allocate resources to other areas of the business.

5. Data-driven Insights: AI algorithms can generate valuable insights from the data collected during the quality control process. These insights can help businesses identify trends, optimize production processes, and make informed decisions to drive continuous improvement.

Implementing AI-driven Quality Control

Implementing an AI-driven quality control system requires careful planning and consideration. Here are some key steps to take:

- Identify the specific quality control processes that can benefit from AI integration.

- Collect and organize relevant data to train the AI algorithms.

- Select or develop AI algorithms that are best suited for the identified quality control tasks.

- Integrate the AI algorithms into the existing quality control infrastructure.

- Monitor and evaluate the performance of the AI-driven system, making necessary adjustments and improvements.

It is important to note that AI-driven quality control systems are not meant to replace human workers but rather to augment their capabilities. Collaborative efforts between AI and human operators can lead to more efficient and effective quality control processes.

The Future of AI-driven Quality Control

The potential of AI-driven quality control is limitless. As AI technologies continue to advance, we can expect even greater levels of accuracy, efficiency, and automation in quality control processes. With the integration of Internet of Things (IoT) devices and data analytics, businesses can create interconnected systems that provide real-time insights and enable predictive maintenance.

Furthermore, AI-driven quality control can be applied to various industries, ranging from manufacturing to healthcare and beyond. The ability to detect defects and anomalies in real-time can help prevent costly disruptions and ensure the highest standards of quality.

In conclusion, AI-driven quality control offers businesses a powerful tool to enhance productivity and efficiency. By harnessing the capabilities of AI algorithms, companies can achieve higher levels of accuracy, reduce costs, and gain valuable insights for continuous improvement. As technology continues to evolve, AI-driven quality control will undoubtedly play a pivotal role in shaping the future of business operations.

Key Takeaways: AI-driven Quality Control for Enhanced Productivity and Efficiency

- AI technology can improve quality control processes in various industries.

- By automating tasks, AI can save time and increase productivity.

- AI-driven quality control can reduce errors and defects in products or services.

- Efficiency can be enhanced by using AI algorithms to analyze large amounts of data quickly.

- Implementing AI-driven quality control can lead to cost savings and improved customer satisfaction.

Frequently Asked Questions

How does AI-driven quality control enhance productivity and efficiency?

AI-driven quality control is revolutionizing industries by automating and streamlining processes to enhance productivity and efficiency. With AI technology, companies can analyze vast amounts of data in real-time, identify patterns, and make data-driven decisions. This not only saves time but also eliminates human error, leading to improved accuracy and reliability.

Additionally, AI-driven quality control systems can continuously monitor operations, detecting anomalies and potential issues before they escalate. By proactively addressing problems, companies can minimize downtime and maximize productivity. Overall, AI-driven quality control empowers businesses to optimize their processes, increase output, and achieve higher levels of efficiency.

What are the benefits of implementing AI-driven quality control?

Implementing AI-driven quality control offers numerous benefits to businesses. Firstly, it enables faster and more accurate quality inspections, reducing the need for manual inspections and increasing throughput. This leads to improved productivity and cost savings.

Furthermore, AI-driven quality control systems can identify defects and anomalies that may go unnoticed by human inspectors. By detecting and addressing these issues early on, companies can prevent costly rework or customer complaints, ensuring higher product quality and customer satisfaction.

How does AI technology optimize quality control processes?

AI technology optimizes quality control processes by leveraging machine learning algorithms to analyze data and identify patterns. By training AI models on historical data, the system can learn to recognize normal and abnormal patterns, enabling it to detect defects or anomalies with high accuracy.

Moreover, AI-driven quality control systems can adapt and improve over time. As new data is collected, the AI models can continuously learn and update their algorithms, making them increasingly effective at identifying issues and optimizing the quality control process.

Can AI-driven quality control replace human inspectors?

While AI-driven quality control systems offer significant benefits, they cannot completely replace human inspectors. Human inspectors bring valuable expertise and intuition that AI technology currently cannot replicate.

However, AI can complement human inspectors by automating repetitive and time-consuming tasks, allowing them to focus on more complex analysis and decision-making. This combination of human and AI capabilities leads to a more efficient and accurate quality control process.

What industries can benefit from AI-driven quality control?

AI-driven quality control has the potential to benefit various industries. Manufacturing industries, such as automotive, electronics, and pharmaceuticals, can leverage AI technology to improve product quality, reduce defects, and increase production efficiency.

Furthermore, industries that rely on quality control for regulatory compliance, such as food and beverage, healthcare, and aerospace, can benefit from AI-driven systems that ensure adherence to strict standards and regulations. Ultimately, any industry that values productivity, efficiency, and high-quality output can benefit from implementing AI-driven quality control processes.

Final Thought: Harnessing the Power of AI for Quality Control

As we wrap up our exploration of AI-driven quality control and its impact on productivity and efficiency, it’s clear that this technology holds immense potential for businesses across various industries. By automating and enhancing quality control processes, AI enables companies to streamline operations, reduce errors, and deliver superior products and services to their customers.

In today’s fast-paced world, where competition is fierce and customer expectations are soaring, integrating AI into quality control systems is no longer a luxury but a necessity. By leveraging machine learning algorithms and real-time data analysis, businesses can uncover valuable insights and make data-driven decisions that drive continuous improvement. AI-driven quality control empowers organizations to identify and address issues proactively, resulting in enhanced productivity, cost savings, and increased customer satisfaction.

In conclusion, the adoption of AI-driven quality control is a game-changer for businesses seeking to stay ahead in a rapidly evolving marketplace. By harnessing the power of AI, companies can unlock new levels of productivity and efficiency, enabling them to thrive in a highly competitive landscape. Embracing this technology not only improves the bottom line but also positions organizations as leaders in their respective industries. So, let’s embrace the future and embark on a journey where AI and quality control work hand in hand to drive success and innovation.