In today’s fast-paced industrial landscape, maximizing productivity and minimizing downtime are key priorities for businesses. That’s why the implementation of AI-powered predictive maintenance has become a game-changer for industrial productivity. By harnessing the power of artificial intelligence and advanced analytics, companies can now proactively identify and address potential equipment failures before they even occur. This revolutionary approach not only saves time and money but also ensures uninterrupted operations, leading to increased efficiency and profitability.

Imagine a world where machines can predict when they need maintenance, just like humans know when to schedule a doctor’s appointment. Well, thanks to AI-powered predictive maintenance, that world is now a reality. Gone are the days of reactive maintenance, where equipment failures would catch businesses off guard, causing costly delays and repairs. With the help of sophisticated algorithms and machine learning, AI technology can analyze vast amounts of data collected from industrial equipment, detecting patterns and anomalies that may indicate a future breakdown. By leveraging these insights, companies can take proactive measures, such as scheduling maintenance tasks or replacing worn-out components, to prevent costly disruptions and keep operations running smoothly.

In conclusion, AI-powered predictive maintenance is revolutionizing industrial productivity by enabling businesses to stay one step ahead of potential equipment failures. By harnessing the power of advanced analytics and artificial intelligence, companies can proactively identify maintenance needs, optimize workflows, and ensure uninterrupted operations. This not only saves time and money but also leads to increased efficiency and profitability. So, if you’re looking to boost your industrial productivity, it’s time to embrace the future and leverage the power of AI-powered predictive maintenance.

AI-powered Predictive Maintenance for Industrial Productivity is revolutionizing the manufacturing sector. By utilizing artificial intelligence and machine learning algorithms, this advanced system can predict equipment failures before they occur, minimizing downtime and maximizing productivity. With real-time data analysis, AI-powered predictive maintenance can identify patterns and anomalies, enabling proactive maintenance strategies. This technology helps businesses reduce costs, increase efficiency, and improve overall equipment effectiveness. Embracing AI-powered predictive maintenance is essential for companies looking to stay competitive in the ever-evolving industrial landscape.

AI-powered Predictive Maintenance for Industrial Productivity

AI-powered predictive maintenance is revolutionizing the industrial sector by leveraging the power of artificial intelligence to optimize maintenance processes and maximize productivity. By analyzing data from various sources, including sensors, machines, and historical maintenance records, AI algorithms can predict potential equipment failures or performance issues before they occur. This proactive approach to maintenance allows companies to avoid costly downtime, improve operational efficiency, and reduce maintenance costs.

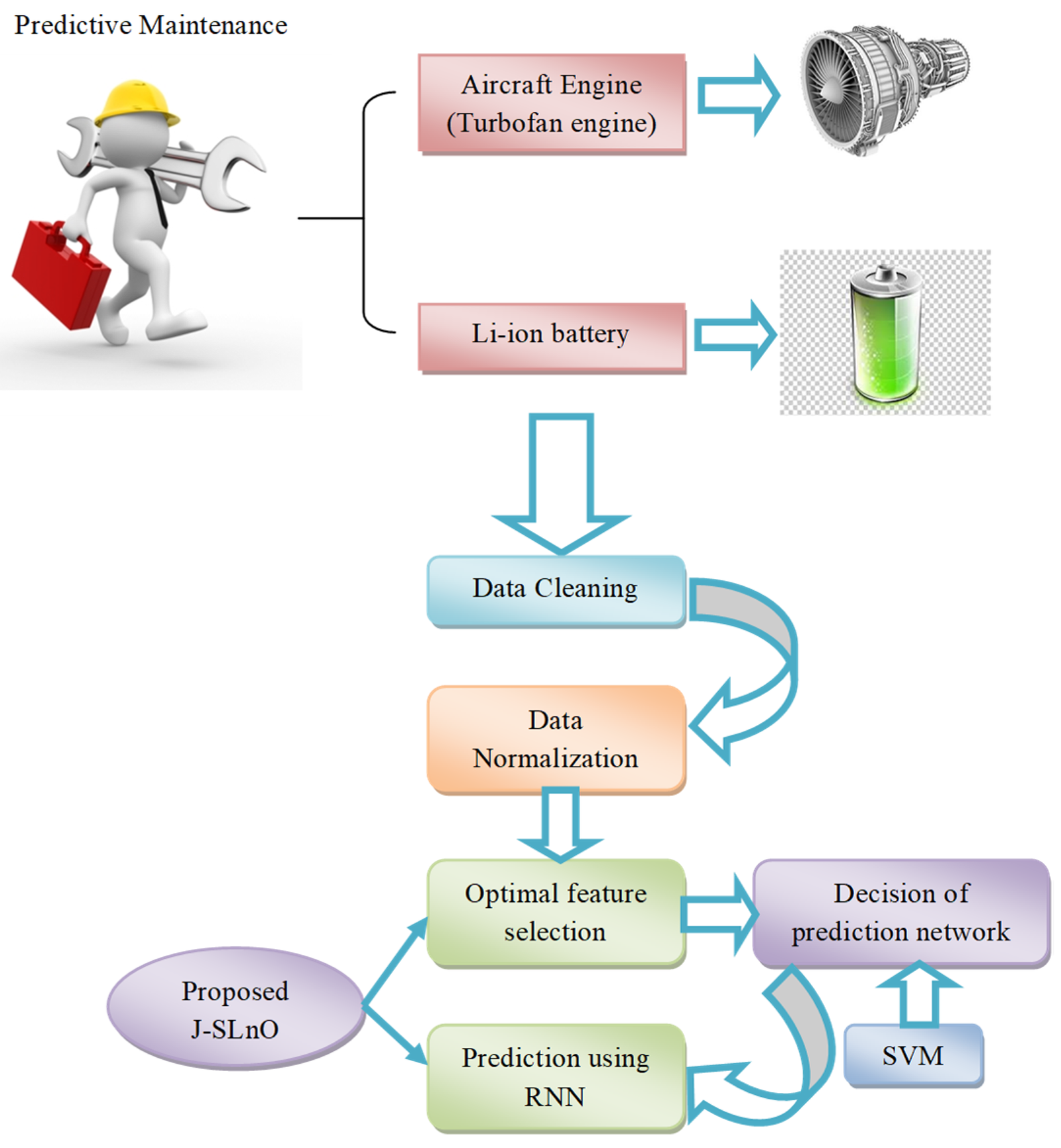

The implementation of AI-powered predictive maintenance begins with the collection and integration of data from different sources. This data includes real-time sensor data, historical maintenance records, and other relevant information. Machine learning algorithms are then applied to this data to identify patterns and anomalies that can indicate potential equipment failures. These algorithms continuously learn and adapt as new data is collected, improving the accuracy of predictions over time.

One of the key advantages of AI-powered predictive maintenance is its ability to detect early warning signs of equipment failure. By continuously monitoring equipment performance and analyzing data, AI algorithms can identify subtle changes in performance that may indicate an upcoming failure. This allows maintenance teams to take proactive measures, such as scheduling maintenance or replacing faulty components, before a complete breakdown occurs. By addressing issues early on, companies can avoid costly unplanned downtime and minimize the impact on production.

In addition to detecting equipment failures, AI-powered predictive maintenance can also optimize maintenance schedules. By analyzing historical data and equipment performance trends, AI algorithms can identify patterns and recommend the most optimal time for maintenance activities. This reduces the need for unnecessary maintenance and ensures that equipment is serviced when it is most likely to need it. By optimizing maintenance schedules, companies can reduce downtime, increase equipment availability, and improve overall productivity.

Another benefit of AI-powered predictive maintenance is its ability to prioritize maintenance tasks based on criticality and impact on productivity. By analyzing data and considering factors such as the importance of equipment to production processes, AI algorithms can determine which maintenance tasks should be prioritized. This ensures that resources are allocated efficiently and that critical equipment receives the necessary attention. By focusing on high-impact maintenance tasks, companies can further improve productivity and minimize disruptions.

AI-powered predictive maintenance also enables condition-based maintenance, where maintenance activities are triggered based on the actual condition of equipment rather than predefined schedules. By continuously monitoring equipment performance in real-time, AI algorithms can detect changes that may require maintenance intervention. This approach allows companies to optimize maintenance efforts and only perform maintenance when it is truly necessary, reducing costs and minimizing downtime.

In conclusion, AI-powered predictive maintenance is a game-changer for industrial productivity. By leveraging the power of artificial intelligence and advanced analytics, companies can proactively detect equipment failures, optimize maintenance schedules, prioritize tasks, and enable condition-based maintenance. This leads to improved operational efficiency, reduced downtime, and lower maintenance costs. Embracing AI-powered predictive maintenance is essential for companies looking to stay competitive in today’s fast-paced industrial landscape.

Key Takeaways: AI-powered Predictive Maintenance for Industrial Productivity

- AI-powered predictive maintenance uses artificial intelligence to anticipate and prevent equipment failures in industries.

- It helps improve productivity by reducing downtime and optimizing maintenance schedules.

- This technology can accurately predict when machines need repairs or maintenance, preventing costly breakdowns.

- By analyzing data from sensors and historical patterns, AI can identify patterns that indicate potential issues.

- Implementing AI-powered predictive maintenance can save companies time, money, and resources.

Frequently Asked Questions

What is AI-powered predictive maintenance?

AI-powered predictive maintenance is a cutting-edge approach to maintenance in industrial settings. It utilizes artificial intelligence algorithms and machine learning techniques to analyze data from various sources, such as sensors and equipment telemetry, to predict when machinery or components are likely to fail. By leveraging advanced analytics, AI-powered predictive maintenance enables businesses to proactively schedule maintenance activities, reduce unplanned downtime, and optimize productivity.

This innovative technology can detect patterns and anomalies in data, identify potential issues before they occur, and provide actionable insights to maintenance teams. By analyzing historical data and real-time information, AI-powered predictive maintenance can identify the optimal time for maintenance interventions, ensuring that resources are used efficiently and downtime is minimized.

How does AI-powered predictive maintenance improve industrial productivity?

AI-powered predictive maintenance plays a crucial role in enhancing industrial productivity. By predicting failures and initiating maintenance activities proactively, it helps reduce unplanned downtime, which can be costly and disruptive. This technology enables businesses to move from a reactive maintenance approach to a proactive one, allowing them to plan maintenance activities in advance and avoid unexpected breakdowns.

Moreover, AI-powered predictive maintenance optimizes the utilization of resources. By accurately predicting when machinery or components will require maintenance, businesses can avoid unnecessary inspections and repairs, saving time and money. This approach also helps in optimizing the availability and performance of critical assets, leading to improved overall productivity.

What are the benefits of AI-powered predictive maintenance?

AI-powered predictive maintenance offers several advantages for industrial productivity. Firstly, it reduces unplanned downtime by identifying potential failures in advance, allowing businesses to address issues before they cause major disruptions. This leads to increased equipment availability and improved operational efficiency.

Additionally, AI-powered predictive maintenance enables cost savings by optimizing maintenance schedules. By avoiding unnecessary maintenance activities and focusing resources on critical assets, businesses can minimize maintenance costs while still ensuring the reliability and performance of their machinery.

How can AI-powered predictive maintenance be implemented in industrial settings?

Implementing AI-powered predictive maintenance in industrial settings involves several steps. Firstly, businesses need to collect and integrate data from various sources, such as sensors, equipment telemetry, and maintenance records. This data is then used to train machine learning models that can predict failures and identify maintenance needs.

Next, businesses need to deploy the trained models into their operational systems, allowing them to continuously monitor and analyze real-time data. This enables the detection of anomalies and deviations from normal operating conditions, triggering alerts and maintenance notifications.

It is also important to establish a collaborative approach between data scientists, maintenance teams, and subject matter experts to ensure effective implementation and utilization of AI-powered predictive maintenance technology.

What industries can benefit from AI-powered predictive maintenance?

AI-powered predictive maintenance can be beneficial for various industries, including manufacturing, energy, transportation, and healthcare. In manufacturing, it can help optimize the performance of production lines and minimize downtime. In the energy sector, it can improve the reliability and efficiency of power generation and distribution systems.

In transportation, AI-powered predictive maintenance can enhance the safety and reliability of vehicles and infrastructure. In healthcare, it can aid in the maintenance of critical medical equipment, ensuring uninterrupted patient care. Overall, any industry that relies on machinery and equipment can benefit from the implementation of AI-powered predictive maintenance to optimize productivity and reduce operational costs.

Final Summary: Revolutionizing Industrial Productivity with AI-powered Predictive Maintenance

In this fast-paced world of industrial productivity, where every second counts and downtime can be costly, AI-powered predictive maintenance has emerged as a game-changer. By harnessing the power of artificial intelligence and data analytics, businesses can now proactively monitor and predict the health of their machinery and equipment, optimizing performance and minimizing unexpected breakdowns. This revolutionary approach to maintenance has not only transformed the way industries operate but has also paved the way for increased efficiency, reduced costs, and improved safety.

With AI-powered predictive maintenance, businesses can say goodbye to the traditional reactive maintenance model, where repairs are made only after a machine fails. Instead, they can embrace a proactive approach, leveraging advanced algorithms and machine learning techniques to detect anomalies, identify potential issues, and schedule maintenance tasks in a strategic manner. By analyzing real-time data and historical patterns, AI algorithms can predict when a machine is likely to experience a failure, enabling businesses to take preventive actions before it’s too late. This not only minimizes costly downtime but also extends the lifespan of equipment and reduces the need for expensive emergency repairs.

By adopting AI-powered predictive maintenance, businesses can unlock a world of possibilities. They can optimize maintenance schedules, reduce unplanned downtime, improve asset reliability, and enhance overall productivity. Moreover, the integration of AI and IoT technologies enables the collection and analysis of vast amounts of data, providing valuable insights into equipment performance and operational trends. With this wealth of information at their disposal, businesses can make data-driven decisions, optimize resource allocation, and continuously improve their processes.

In conclusion, AI-powered predictive maintenance is revolutionizing industrial productivity by enabling businesses to proactively monitor and maintain their machinery and equipment. By harnessing the power of artificial intelligence and data analytics, companies can optimize performance, reduce costs, and enhance safety. This transformative approach not only shifts maintenance practices from reactive to proactive but also empowers businesses with valuable insights for data-driven decision-making. As industries continue to embrace AI-powered predictive maintenance, the future holds immense potential for improved operational efficiency, increased profitability, and sustained growth.